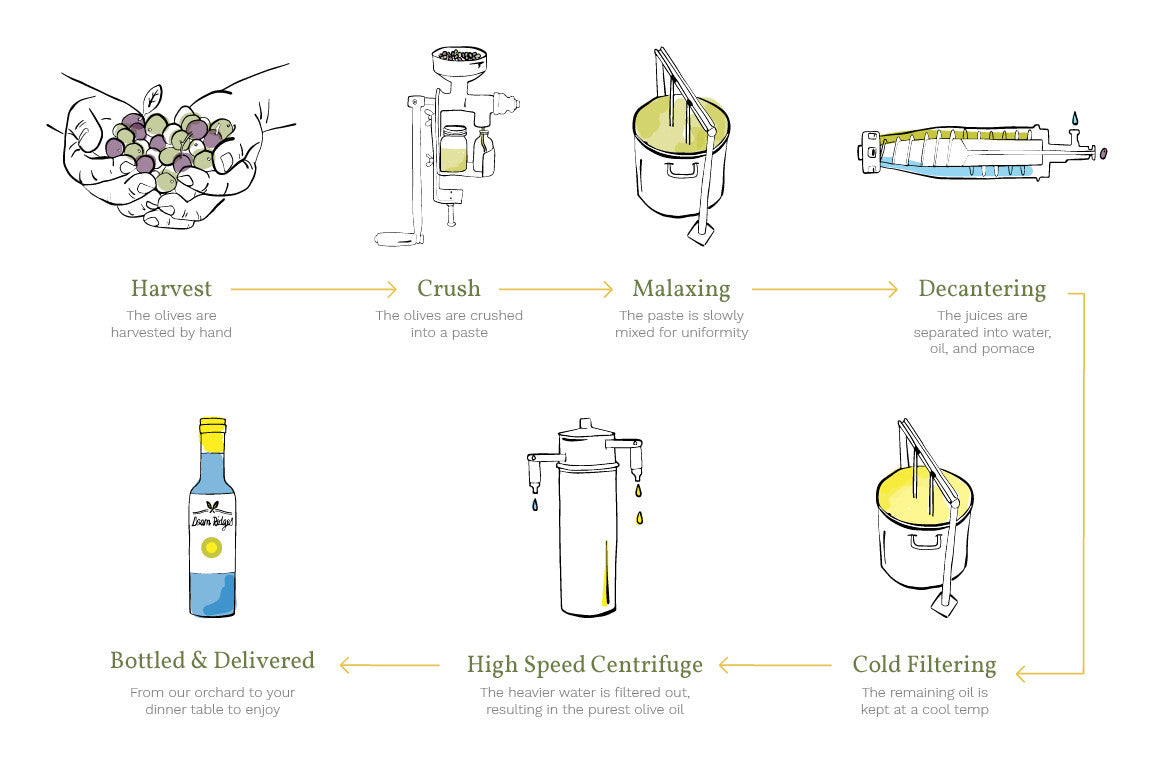

How Loam Ridges Olive Oil is Made

Humans have been enjoying the fruit of the olive tree for thousands of years. In fact, there are carvings on the walls of the pyramids displaying ancient pharaohs enjoying the food.

Here at Barcoloux Family Orchards, we’ve been growing and tending our olive trees for over 100 years. During this time we have continued to perfect our craft to bring the best olive oil to your table using “California Fresh” agriculture methods. Our unique process results in a golden color as perfect as the California Sun.

How Olive Oil is Made

Harvest

Some time between August and through November our olive groves are ready to be picked. There are many ways to accomplish harvesting the olives, including using machines or racks to shake the trees that result in the olives falling to a waiting tarp on the ground. Our process is precisely the same as centuries ago. We still hand harvest all the olives once they have reached the perfect stage.

Crushing

Once the olives are picked, they are immediately transported to the mill to be crushed as they tend to sour if left alone for just one day.

The crushing process turns the olives into a paste helps release the oils trapped within. This process has been perfected over the years to extract as much oil out of each olive as possible. By crushing the olives into a paste, the flesh cells facilitate the release of oil for the vacuoles.

Malaxing

Once crushed the olive paste enters the malaxing phase of the process which allows small oil drops to combine into larger ones. This also ensures the paste develops a uniformity and consistency over the production run.

Decantering

The olive paste that remains after malaxing has a combination of oil, water, and pomace that needs to be separated. To accomplish this Loam Ridges uses a unique blend of decentering and cold filtering.

Cold Filtering

Many producers of olive oil have gone away from the “Cold Extraction” method of separating the oil, but we insist on continuing the practice as it helps give our oil it’s distinct, buttery aroma and taste. In fact, our paste never is heated above 27 degrees C, ensuring that none of the flavors of the olives are cooked out.

High-Speed Centrifuge

Finally, the remaining mixture reaches the high-speed centrifuge which finishes separating the water, particles, and oil. The centrifuge spins at a 3000 rpm which divides the material into solids, water, and oils. This method is the cleanest and most accurate finishing step to produce exceptional quality Olive Oil.

Bottling the Oil

Once the oil has met our stringent quality checks, it is individually bottled in our signature dark blue bottles to protect the product from damaging UV light.

From our Northern Californian orchards to your dinner table, now you know how we make the highest quality olive oil, we hope you will order a bottle to share with your friends and family.